current position:Home > Product > Intelligent automatic grinding >

D54R series CNC automatic diameter axial grinding machine

source:Jinan Lianfei CNC Equipment Co., Ltd. date:2019-03-28 16:17:08

1. This special equipment is mainly used for thermoforming rolling of various large and super large ring parts in gear, bearing, wind power, military, aerospace and other industries.

2. The rolling ring has the characteristics of high precision grade and small cutting allowance.

3. The equipment is mainly composed of main transmission box, bed, main slider, main roller, axial frame, centering mechanism, measuring device, hydraulic system, hydraulic pipeline, control system, crawler device, lubrication system and cooling system. And so on.

4. The numerical control program is independently researched and developed by the company, realizing the rolling process is truly automatic, without manual intervention, greatly improving the ring product yield and rolling efficiency.

5. We can also customize development according to the specific requirements of users.

The latest operating system is compared with the old system

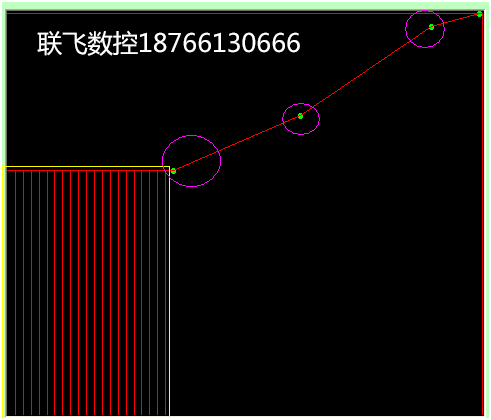

New system curve interface:

Lianfei CNC 18766130666

The yellow frame is indicated by the target ring interface, and the entire black frame is indicated by the blank ring interface. The rolling curve can be modified by the three green dots in the purple circle frame above. Left mouse button clicks a point and drags, the curve follows the change, to the desired position, release the left mouse button.

There are two types of rolling:

(1) Place the working mode selector knob in the “manual” position and press the “rolling start” button to enter the manual rolling state. “Operation in rolling” is displayed on the operation interface, indicating that the ring has entered the rolling state. At this time, it is in the manual rolling state. All knobs require manual operation.

(2) Put the working mode selector knob in the “automatic” position, press the “rolling start” button, and the system will enter the automatic rolling.

The old system uses serial communication and the data transmission is slow. The new system uses network-type Ethernet communication, which uses the Ethernet interface of the host computer and the Ethernet interface of the PLC to communicate at a transmission speed of 100M/s. Any data in the production process of the device is transmitted to the main interface without delay, and is sent to the operator. A faster reference.

In the above figure, the red curve is the rolling curve set by the operator, the green line is the rolling curve in the actual production process, and the radial and axial directions are automatically rolled along the set curve. There are no errors.

Our system is currently used in Sany Group, Huzhou Xinzi Seiko, Changzhou Shuangqiang, and Anhui Tongsheng Ring. Obtained recognition from customers. Below is a photo of the equipment when it is rolled on site.

Lianfei CNC 18766130666

Lianfei CNC 18766130666

The old and new systems are compared as follows:

| Old System | New System | ||

| Radial Rolling< /span> | Manual manual control | Auto | |

| Axial rolling< /span> | Manual manual control | Auto | |

| Holding the roll | Manual manual control | Auto | |

| Front correction | Manual manual control | Auto | |

| lifting the roll | Manual manual control | Auto | |

| Over the reference point | Must be turned on | None | |

| Ring accuracy | Normal Accuracy | Normal Accuracy | |

| Communication speed | 192KString OK | 100MNetwork cable | |

| One-click control | No, Pure manual operation | YES | |

| PLCModel | Japan Mitsubishi | Siemens, Germany | |

| Encoder | Domestic relative encoder< /span> | Import Bus Data Encoder | |

| Operation Desk | The buttons are cumbersome and complex. | Simple, efficient, and intuitive | |

| Key Overflow Valve< /span> | Rexus Relief Valve< /span> | Rexroth Relief Valve< /span> | |

| Key Flow Valves | Rexus Flow Valve | Rexroth high-frequency proportional servo valve |

The new system has a small amount of spare parts and high precision, which saves users and saves money.

Previous page:第一页

Related Products

15863157870,18766130666

0531-88766192

18766130666@139.com

2766 Yingxiu Road, High-tech Zone, Jinan City